Industrial IoT visualization: How Grafana powers industrial automation and IIoT

From real-time asset monitoring to observing smart robots, Grafana has become a go-to visualization tool for industrial automation and IIoT.

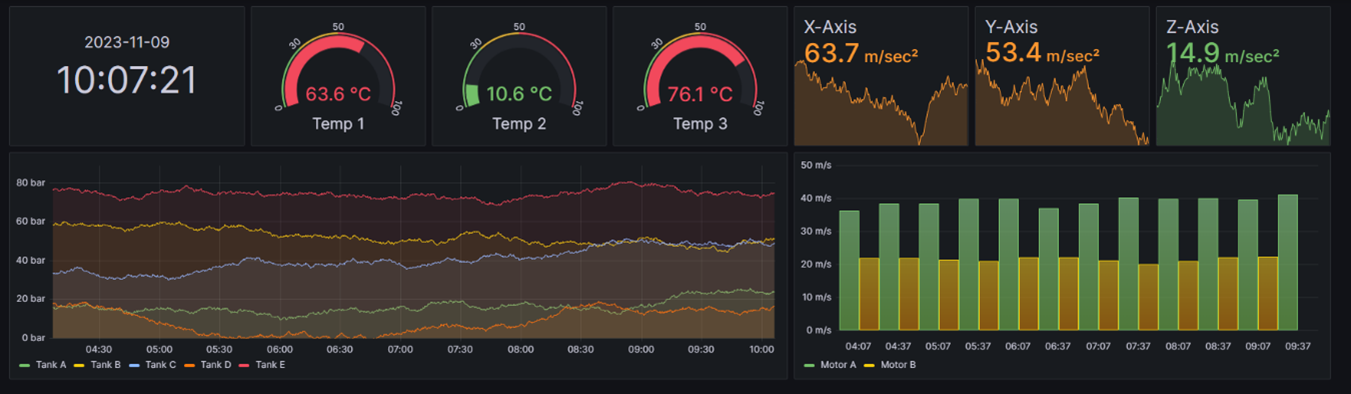

“Dashboards built with Grafana display data from all layers of the manufacturing enterprise: from the boardroom all the way to the shop floor,” wrote Denis Gontcharov, developer advocate, and Jeremy Theocharis, co-founder and CTO, at United Manufacturing Hub (UMH) — a startup that uses Grafana as part of its open source IT/OT Integration Platform — in a recent blog post. “While the CEO observes their company’s high-level financial KPIs, the machine operator can keep a watchful eye on critical parameters.”

In this post, we explore some of the top reasons companies choose Grafana for IIoT use cases, the benefits they’ve seen, and why, increasingly, organizations in the manufacturing and industrial automation sector use Grafana to deliver data visualization, alerting, and reporting capabilities to their end users.

Why Grafana for industrial automation and IIoT

Centralized view of real-time data

Providing a centralized view into diverse data sets has always been a key feature of Grafana. But it’s also a feature that’s especially valuable for companies in the IIoT and manufacturing verticals, where data is generated from such a wide range of systems, machines, and sensors.

“Given Grafana’s single-pane-of-glass approach to data integration, visualizing data from disparate sources is very convenient: there is no need to combine the data in a backend store or some other vendor’s database,” wrote Gontcharov and Theocharis of UMH. “You can unify all your data wherever it lives.”

Grafana is a core component of UMH’s open source IT/OT Integration Platform. The system operates by extracting data from various sources, such as programmable logic controllers (PLCs), and then streamlines that data into a central integration point known as the Unified Namespace. This framework utilizes MQTT and Kafka to ensure robust data handling.

Within this Unified Namespace, time series data is systematically organized and stored. Together with TimescaleDB, Grafana forms an essential part of this open source setup, helping users visualize time series data from manufacturing and IIoT devices.

“Grafana excels at making beautiful, real-time visualizations of important process metrics and KPIs, such as temperature, flow rates, and overall equipment effectiveness,” explained Gontcharov and Theocharis. “This way, operators can quickly inspect and diagnose the production process.”

Provide end users with out-of-the-box visualizations, alerting, and more

More and more, companies are turning to Grafana to power their own commercial apps and services targeted at the industrial automation and IIoT space.

These companies — who collaborate with Grafana Labs via an OEM partnership — typically embed, white-label, or distribute Grafana within their own offerings to provide data visualizations, alerting, and reporting capabilities directly to their end users.

For example, Comact, a leader in transformational wood processing, white-labels and distributes Grafana as the monitoring interface for OPER8, their IIoT solution that provides customers with real-time visibility into production and asset health.

“We chose Grafana OEM as the visualization layer on top of our IIoT product due to requirements we had around visualizing data in real-time, alerting, and RBAC,” said David Gauthier, VP Digital Technology at Comact. “Our customers have been very happy with the solution and it’s equipped our internal team and customers alike to ensure their facilities are up and running 100% of the time.”

The Global BPO business unit at Canon, meanwhile, leverages Grafana to deliver services to their customers, including those in the manufacturing industry.

“Grafana has provided us more insights into our customers’ environments and the ability to share these insights directly with our customers, allowing us to deliver a more comprehensive service,” said Roy Wong, Systems Management Engineer, Canon Business Services.

And then there’s Siemens, the global leader in industrial automation, who embeds Grafana within Dashboard Designer, the visualization component of their Insights Hub IIoT platform. The app empowers industrial manufacturers to create dashboards to monitor everything from overall equipment effectiveness (OEE) to an individual device’s energy consumption.

Interested in an OEM partnership with Grafana Labs? Please reach out to your Grafana Labs account team for support.

Observability at scale

IIoT devices can generate massive amounts of data. That’s why, to effectively collect and analyze that data, you need an observability platform that can scale.

At Dexory, a warehouse intelligence platform provider, scalability was a big factor in their decision to use Grafana Cloud. Dexory deploys fleets of autonomous robots to help some of the world’s biggest logistics providers and manufacturers monitor warehouse operations and product inventory.

“We install this robot and, every night, it drives around your warehouse by itself and takes an inventory of all the items that are stored in your warehouse and on the racking system,” explained Matt MacLeod, VP Software at Dexory at ObservabilityCON on the Road in London. “It scans about 10,000 items every hour for barcodes, takes pictures of them, and then measures the dimensions using 3D scanners.”

To ensure those robots are performing optimally, and providing manufacturers with the insights and data they need to streamline their operations, Dexory needed an observability solution of its own.

“Without observability, that fleet of robots is a bit of a black box,” MacLeod said.

The company originally built a metrics system in 2019 using the TICK stack — Telegraf, InfluxDB, Chronograf, and Kapacitor — for fleet status notifications, such as lost connectivity or unexpected power loss. And while this solution worked well initially, scaling was a challenge due to reliability demands and having to maintain a self-hosted system.

That’s when Dexory turned to Grafana Cloud.

“Your data volumes are going to increase more than you think, and having the tools in place to handle that scaling is going to be important,” MacLeod said, adding: “Coming back to why we are using Grafana Cloud, that’s one of the key reasons: it’s really been one of those things that lets us scale very quickly.”

Ease of use

Another common reason companies turn to Grafana for IIoT use cases is ease of use.

“Once the data is made available in Grafana, it’s easy to create beautiful visualizations,” wrote Gontcharov and Theocharis.

In fact, over the years, a number of companies in the manufacturing and IIoT space — including Varland Plating and American Metal Processing — have cited a low barrier to entry and simplified data collection as some of the biggest factors behind their decisions to adopt Grafana.

The large open source community surrounding Grafana is also a powerful resource for new users to tap into.

“The availability of public knowledge makes it easy for inexperienced users to find help and ramp up quickly,” Gontcharov and Theocharis explained. “This means manufacturers won’t get stuck on some niche edge case.”

To learn more about using Grafana for IIoT use cases, please check out these blog posts and case studies.